Strapping

Steel Strap, Polyester Strap, Polypropylene Strap, Polywoven Strap and Composite Strap.

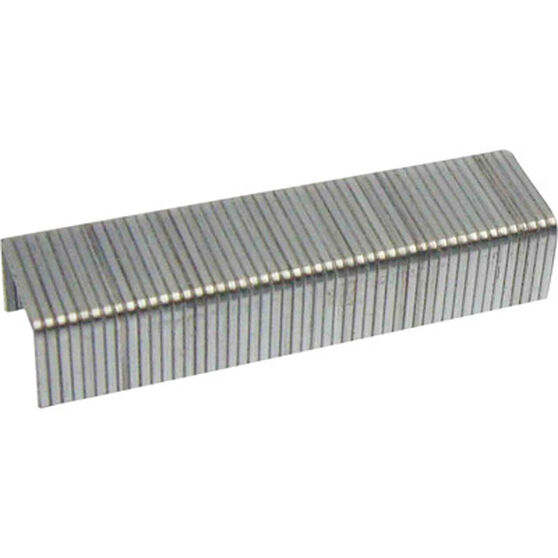

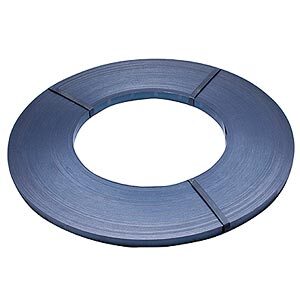

Steel Strap

-

-

Starter Kit Steel Strap 16mm

$362.95 -

Sealer 32mm Single Notch

$306.00 -

-

Sealer / Crimper MIP1100 19mm

$130.00 -

Sealer / Crimper MIP 3000 19mm

$650.00 -

-

S19mm Steel Sealer / Crimper

$66.00 -

S16mm Steel Sealer / Crimper

$59.95 -

ZR34 19mm Steel Seal / Clip

$117.00 -

5436P 32mm Steel Seal / Clip

$85.60 -

-

-

Starter Kit Steel Strap 16mm

$362.95 -

Sealer 32mm Single Notch

$306.00 -

-

Sealer / Crimper MIP1100 19mm

$130.00 -

Sealer / Crimper MIP 3000 19mm

$650.00 -

-

S19mm Steel Sealer / Crimper

$66.00 -

S16mm Steel Sealer / Crimper

$59.95 -

ZR34 19mm Steel Seal / Clip

$117.00 -

5436P 32mm Steel Seal / Clip

$85.60 -

Polyester Strap

-

-

Starter Kit Polyester Strap 16mm

$907.40 -

Sealer / Crimper ORZ3200 16mm

$251.59 -

-

Sealer / Crimper PET 15

$87.00 -

Sealer / Crimper PET 12

$67.00 -

OFEC 16mm Seal / Clip

$111.50 -

OFEC 13mm Seal / Clip

$77.00 -

-

-

-

-

-

Starter Kit Polyester Strap 16mm

$907.40 -

Sealer / Crimper ORZ3200 16mm

$251.59 -

-

Sealer / Crimper PET 15

$87.00 -

Sealer / Crimper PET 12

$67.00 -

OFEC 16mm Seal / Clip

$111.50 -

OFEC 13mm Seal / Clip

$77.00 -

-

-

-

Polypropylene Strap

-

-

-

-

-

OFHD 19mm Poly Seal / Clip

$52.00 -

OFHD 15mm Poly Seal / Clip

$48.00 -

OFHD 12mm Poly Seal / Clip

$46.00 -

OF 19mm Poly Seal / Clip

$46.25 -

OF 15mm Poly Seal / Clip

$30.00 -

OF 12mm Poly Seal / Clip

$34.50 -

Polypropylene 19mm Starter Kit

$292.20 -

Polypropylene 12mm Starter Kit

$240.00

-

-

-

-

-

OFHD 19mm Poly Seal / Clip

$52.00 -

OFHD 15mm Poly Seal / Clip

$48.00 -

OFHD 12mm Poly Seal / Clip

$46.00 -

OF 19mm Poly Seal / Clip

$46.25 -

OF 15mm Poly Seal / Clip

$30.00 -

OF 12mm Poly Seal / Clip

$34.50 -

Polypropylene 19mm Starter Kit

$292.20 -

Polypropylene 12mm Starter Kit

$240.00

Composite Strap

-

Baling Strap 13mm White

$45.00 -

Composite Strap 32mm

$132.00 -

Composite Strap 19mm

$94.80 -

Composite Strap 16mm

$110.00 -

-

-

-

Composite Strap Tensioner H/D

$415.00 -

P350 Tensioner Poly Strap

$98.50

-

Baling Strap 13mm White

$45.00 -

Composite Strap 32mm

$132.00 -

Composite Strap 19mm

$94.80 -

Composite Strap 16mm

$110.00 -

-

-

-

Composite Strap Tensioner H/D

$415.00 -

P350 Tensioner Poly Strap

$98.50

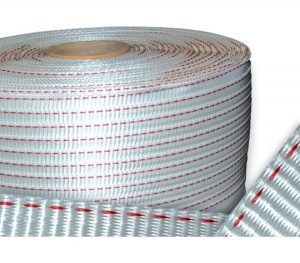

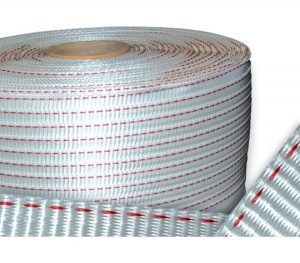

Polywoven Strap

-

Polywoven Strap 19mm x 2 Redline

$105.00 -

Polywoven Strap 19mm x 1 Redline

$120.00 -

-

Polywoven Strap Dispenser

$170.00 -

32mm H/D Metal Buckle

$128.00 -

19mm H/D Metal Buckle

$125.00 -

16mm H/D Metal Buckle

$134.15 -

Strap Lance

$25.00 -

Polywoven Lever Tensioner

$50.00 -

P350 Tensioner Poly Strap

$98.50

-

Polywoven Strap 19mm x 2 Redline

$105.00 -

Polywoven Strap 19mm x 1 Redline

$120.00 -

-

Polywoven Strap Dispenser

$170.00 -

32mm H/D Metal Buckle

$128.00 -

19mm H/D Metal Buckle

$125.00 -

16mm H/D Metal Buckle

$134.15 -

Strap Lance

$25.00 -

Polywoven Lever Tensioner

$50.00 -

P350 Tensioner Poly Strap

$98.50

Steel is the highest tensile strength strapping. It is available in a variety of widths and thicknesses as well as variations in the grade of steel. Steel is used for heavy duty holding where high strength and minimal stretch are desired. Surface finishes for steel strap include paint and wax or zinc and wax. The wax is used to better transmit the tension around the bundle and for use with certain types of tensioners. Steel strapping is sold by weight rather than length, due to the natural expansion and contraction of steel in the manufacturing process.

What is the difference between Polypropylene (PP) and Polyester (PET) strapping?

Polypropylene (PP) is economical and light-weight strapping. PP is designed for lighter applications. Polyester (PET) strapping is made from high-tenacity polyester yarns and is suitable´ for a variety of industries. To see a comparison sheet on the various types of strap click here.

Which strapping has the highest break load?

Steel Strapping is stronger than Polyester (PET) strapping by 12% for 19mm, 18% for 16mm and a whopping 52% for 13mm Strap. And that does not take into consideration Hi Tensile Steel Strapping which is even stronger. For a comparison sheet on the various types of strap click here.

What does ‘break load’ mean?

‘Break load’ or ‘break strength’ refers to the amount of force required to break or snap the strap. The break load specifications of your strapping should be much higher than the expected force it will be exposed to.

Can you re-use strapping?

Polywoven Strap is the only strap that should be reused. Polypropylene strap held by Buckles can be re-tensioned

What strapping goes with which buckles/accessories?

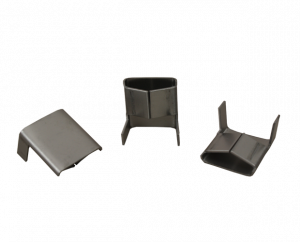

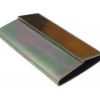

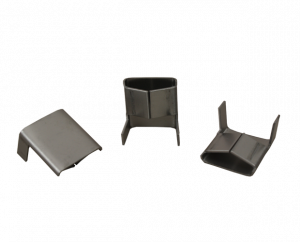

Standard Steel Strap can use either SO (Snap On) Seals (Clips) or for stronger holding a PNSC Seal. 3436P Seals are to be used with Hi Tensile Strap.

Polyester Strap, up to 16mm, can use OFEC Seals. 19mm Strap must be sealed with a Friction Weld, Battery or Pneumatic, Tool. Click here for Friction Weld Strap Tools.

Polywoven Strap uses Phosphated Buckles & Composite Strap uses Zinc coated Buckles. Don’t get them mixed up!

Polypropylene Strap can be used with Plastic or Metal Buckles, OF Seals for Blue Strap or OFHD seals for Black Strap.

Which strapping is right for my application?

This is guided by the weight you are transporting. The heavier the product the stronger the strap you need. For a Strap Comparison Sheet click here.

Is steel strapping safe?

Yes, it is! Used properly with the correct tools and safety considerations you should not have any problems. Call our office and we can show your staff the correct procedure to allay any concerns.

What safety equipment is required when handling strapping?

Gloves should always be worn. You may consider Safety Glasses as well. Check with your OHS supervisor or call our office to discuss your concerns.

How do I order a strapping machine?

Call our office to arrange for a Salesperson to discuss the various machines for various strap.

What does ‘embossed’ strapping mean?

Embossed strapping has a diamond shaped texture and provides friction against the strapping buckle or seal, therefore reducing slipping throughout transit.

Is Polyester (PET) strapping weather resistant?

Polyester & Polypropylene are naturally UV resistant and are virtually weatherproof.

Do you have any strapping starter packs available?

We have several starter packs available for purchase for different types of Strap

Look in the menu according to the type of strap you want. Not sure what you need? Click here for a Strap Comparison Sheet

Can I use a tensioner for hand strapping?

Polypropylene Hand Strap can be used with a P350 Tensioner and PSL Sealer (crimper).

Do you sell edge and corner protectors?

Yes we do. From 50mm wide up to 2100mm long. To see our range of edge protection click here.

What is the difference between strapping tape and packaging tape?

Strapping Tape is used for the palletizing and bundling of lightweight goods without leaving any residue. Strapping Tape has a high impact strength and won’t break during transit or movement around the warehouse. Can be used with a dispenser. Packaging Tape is mainly used to close cartons and packages. Not usually used direct onto your product as it may leave a residue of adhesive.

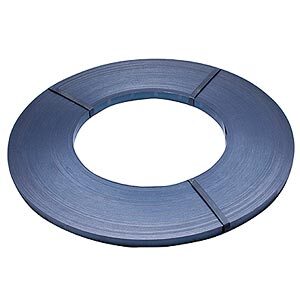

What is the difference between Ribbon Wound and Rope Wound steel strapping?

Ribbon wound strapping is wound onto itself so that the width of the coil is one strand wide and therefore the same width as the strap e.g. 19mm strapping is a coil 19mm wide. Ribbon wound coils weigh approximately 16kg. This makes it light enough to carry around your worksite using a simple Dispenser. We have two ribbon wound strapping dispensers – 13-19mm ribbon wound dispenser and a 32 mm ribbon wound steep strap dispenser.

Rope wound coil will weigh approximately 45kg and is wound uniformly and tightly onto an inner ring (much like a garden hose). Given the weight, these coils are usually placed and stored on dispensers that have wheels. Click her for a rope wound strap dispenser.